Musto's Hematoxylin

for Elastic Fibres

Materials

Stock hematoxylin

| Material | Amount | |

|---|---|---|

| Hematoxylin | 2 | g |

| Ethanol, 95% | 100 | mL |

Stock ferric chloride

| Material | Amount | |

|---|---|---|

| Ferric chloride, hexahydrate | 12.4 | g |

| Distilled water | 500 | mL |

| Hydrochloric acid, concentrated | 5 | mL |

Stock iodine

| Material | Amount | |

|---|---|---|

| Potassium iodide | 4 | g |

| Iodine | 2 | g |

| Distilled water | 100 | mL |

Thiosulphate solution

| Material | Amount | |

|---|---|---|

| Sodium thiosulphate | 5 | g |

| Distilled water | 100 | mL |

Working solution

| Material | Amount | |

|---|---|---|

| Stock hematoxylin | 30 | mL |

| Stock ferric chloride | 20 | mL |

| Stock iodine | 10 | mL |

Tissue Sample

A 10% Formalin variant is suitable. Paraffin sections at 5µ are preferred.

Protocol

- Bring sections to water via xylene and ethanol.

- Place sections in Bouin’s fluid at 60°C for 1 hour.

- Remove the yellow colouration with running tap water.

- Place in working solution for 45 minutes.

- Wash well with tap water, then rinse with distilled water.

- Place into thiosulphate solution for 2 minutes to remove iodine discolouration.

- Wash well with tap water, then rinse with distilled water.

- Counterstain with Van Gieson.

- Dehydrate with absolute ethanol.

- Clear with xylene and mount with a resinous medium

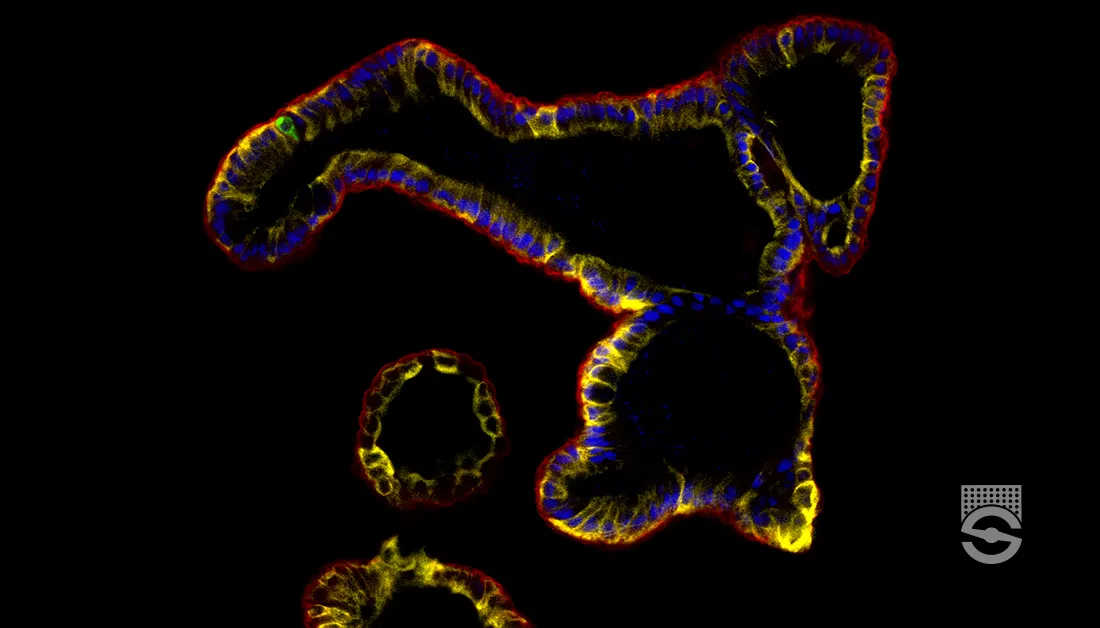

Expected Results

- Nuclei – black

- Elastic fibres – black

- Muscle – yellow

- Collagen – red

Notes

- The original paper recommended counterstaining with a modification of the HPS.

- The treatment with Bouin’s solution is likely included to improve an HPS stain. It may be possible to eliminate it for counterstaining with Van Gieson.

- This is a modification of Verhöeff’s hematoxylin which does not require differentiating, although the Van Gieson counterstain may diminish the intensity of the stain.

Safety Note

Prior to handling any chemical, consult the Safety Data Sheet (SDS) for proper handling and safety precautions.

References

- Musto, Linda, (1981),

Improved iron-hematoxylin stain for elastic fibers.,

Stain Technology, v 56, page 185-7.